Biological Safety Cabinet

When properly maintained and used in conjunction with good laboratory techniques, BSCs provide effective primary containment for work with human pathogens. In containment level 2 facilities, BSCs are used for procedures with the potential to produce infectious aerosols and for high concentrations or large volumes of infectious material. In containment levels 3 and 4, all open vessel activities with infectious materials are conducted in a BSC. Every employee working in a BSC must be trained in its correct use and have a good understanding of the different types of cabinets and how they work.

Classes and Characteristics of Biological Safety Cabinets

There are three classes of BSC: Class I, Class II and Class III. Selection of the proper class of BSC requires careful evaluation of the activities to be carried out. Horizontal, clean benches that direct air towards the operator are not biological safety cabinets and must not be used for handling infectious, toxic or sensitizing materials.

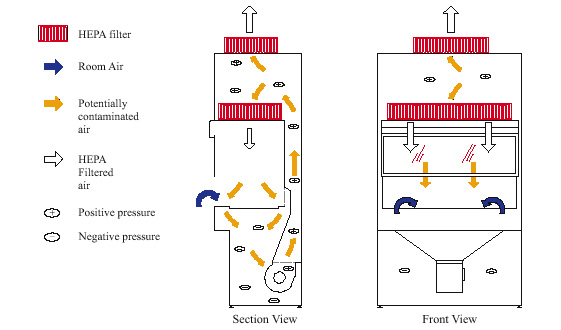

Class I Cabinets (Figures 1a and 1b)

These cabinets have unrecirculated airflow away from the operator that is discharged to the atmosphere after filtration through a HEPA filter. They provide good operator protection but do not protect the material within the cabinet (the product) from contamination.

Fig. 1a. CLASS I BIOLOGICAL SAFETY CABINET (Used in conjunction with the building system. Glove ports are optional.)

Fig. 1b. CLASS I BIOLOGICAL SAFETY CABINET (Complete with internal motor/blower assembly. HEPA filtered exhaust air vented to the atmosphere. Glove ports are optional.)

Class II, Type A1 Cabinets (Figure 2)

- Cabinet air may be recirculated back into the laboratory or ducted out of the building by means of a “thimble” connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter).

- Maintain a minimum average face velocity of 0.38 m/s (75 ft/min).

- May have positive pressure contaminated ducts and plenums.

- Are not suitable for work with low levels of volatile toxic chemicals and volatile radionuclides.

Fig. 2. CLASS II TYPE A1 BIOLOGICAL SAFETY CABINET (Can be room re-circulated or air gap type (thimble).)

Class II, Type A2 Cabinets (Figure 3)

- Cabinet air may be recirculated back into the laboratory or ducted out of the building by means of a “thimble” connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter).

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Have ducts and plenums under negative pressure.

- Is suitable for work with minute quantities of volatile toxic chemicals and trace amounts of radionuclides.

Class II, Type B1 Cabinets (Figure 4)

- Hard-ducted through a dedicated duct exhausted to the atmosphere after passage through a HEPA filter; contain negative pressure plena.

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Recirculate 30% of the air within the cabinet.

- Suitable for work with low levels of volatile toxic chemicals and trace amounts of radionuclides.

Fig. 4. CLASS II TYPE B1 BIOLOGICAL SAFETY CABINET (Hard-ducted.)

Class II, Type B2 Cabinets (Figure 5)

- Does not recirculate air within the cabinet.

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Hard-ducted through a dedicated duct exhausted to the atmosphere, 100% of cabinet air, after passage through a HEPA filter; contain negative pressure plena.

- Suitable for work with volatile toxic chemicals and radionuclides.

The exhaust canopy must allow for proper BSC certification. An alarm should be provided that is audible at the cabinet to indicate loss of exhaust flow from the building exhaust system. The cabinet internal fan should also be interlocked to shut down when the building exhaust system fan fails, to prevent pressurization of the cabinet.

Fig. 5. CLASS II TYPE B2 BIOLOGICAL SAFETY CABINET (Hard-ducted.)

Class III Cabinets (Figure 6)

Class III cabinets are totally enclosed and gas-tight with HEPA filtered supply and exhaust air. Work is performed with attached long-sleeved gloves. The cabinet is kept under negative pressure of at least 120 Pa (0.5 in. w.g.), and airflow is maintained by a dedicated exterior exhaust system. Class III cabinets protect the worker and the product. They are designed for work with level 4 pathogens and provide an alternative to the positive-pressure suit made for maximum containment laboratories. Cabinet lines consisting of several Class III cabinets (e.g., for centrifuges, animal cages, incubators, refrigerators) and transfer devices joined together are traditionally custom built. Specific guidance on the unique requirements for constructing, installing, certifying and using Class III cabinet lines can be found elsewhere. The exhaust air is double HEPA filtered or treated by HEPA filter and incineration. Removal of materials from the cabinet must be through a dunk tank, double door autoclave or air-lock pass-through for decontamination. Interlock or protocols must be used for the autoclave and pass-through doors to prevent both doors from being open at the same time.

Fig. 6. CLASS III BIOLOGICAL SAFETY CABINET (Hard-ducted.)

Use of the Cabinet

Follow these start-up procedures when preparing for work in the BSC:

- Turn off UV lights if in use and ensure that the sash is in the appropriate position.

- Turn on fluorescent light and cabinet blower, if off.

- Check the air intake and exhaust grilles for obstructions.

- If the cabinet is equipped with an alarm, test the alarm and switch it to the “on” position.

- Confirm inward airflow by holding a tissue at the middle of the edge of the viewing panel and ensuring that it is drawn in.

- Disinfect the interior surfaces with a suitable, noncorrosive disinfectant.

- Assemble all materials required for the procedure and load them into the cabinet; do not obstruct the air grilles; the working surface may be lined with absorbent paper with plastic backing; segregate “clean” items from “contaminated” items.

- Wait 5 minutes to purge airborne contaminants from the work area.

Follow these procedures for working in the cabinet :

- Don protective clothing and gloves as appropriate.

- Perform operations as far to the rear of the work area as possible.

- Avoid movement of materials or excessive movement of hands and arms through the front access opening during use; when you do enter or exit the cabinet, do so from straight on; allow the cabinet to stabilize before resuming work.

- Keep discarded, contaminated material to the rear of the cabinet; do not discard materials in containers outside of the cabinet.

- Do not work with open flames inside the cabinet.

- If there is a spill during use, surface decontaminate all objects in the cabinet; disinfect the working area of the cabinet while it is still in operation (do not turn the cabinet off).

Follow these procedures upon completion of the work :

- Allow the cabinet to run for 5 minutes with no activity.

- Close or cover open containers before removing them from the cabinet.

- Surface disinfect objects in contact with contaminated material before removal from the cabinet.

- Remove contaminated gloves and dispose of them as appropriate; wash hands.

- Don clean gloves, and ensure that all materials are placed into biohazard bags within the cabinet.

- Using a suitable non-corrosive disinfectant (e.g., 70% ethanol), disinfect interior surfaces of cabinet; periodically remove the work surface and disinfect the area beneath it (including the catch pan) and wipe the surface of the UV light with disinfectant.

- Turn off the fluorescent light and cabinet blower when appropriate (some cabinets must be left on at all times; if you are unsure, check with your cabinet certifier, safety officer or building maintenance personnel).

- Turn on the UV light if appropriate (do not turn on when people are working close by); UV must be tested to ensure that it is emitting a germicidal wavelength (ask your cabinet certifier to perform this test).

Unit Description:

- Construction are Stainless Steel Body OR CRCA Powder coated

- Differential Pressure Gauge

- Milky White Light

- Feather Touch

- Motor Blower Assemblies : 0.5 HP, ~230 V, 1 phase, 50 Hz

- HAPA Filters (Final Filter) : H13, Efficiency 99.97% down to 0.3µ

- Prefilters : EU6, Efficiency 95% down to 5µ

OPTIONAL ACCESSORISE:

\

- Stainless steel perforated grille for HEPA Filter

- Glove ports

- Filter blocked alarms

- Stands

- Hour meter

- Ultraviolet light

Biological Safety Cabinet is with a variety of standard dimensions. Also our booths can be custom engineered to any size.

Technical Specifications:

| Clean Level: | 100 particles of size 0.5µ / F³ |

|---|---|

| ISO Class: | 5(ISO 14644-1:1999 (E)) |

| Light intensity: | > 300 lux |

| Air Velocity: | 90 FPM (0.45MPS) ± 20 % |

| Noise Level: | <65 DB (A scale) |

| Vibration: | <2.5m (0.0001”) |

| Power Supply: | ~230 V, 1 phase, 50 / 60 Hz |